Description

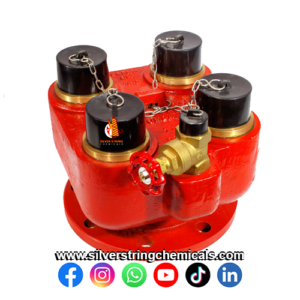

Bristol UL Listed Foam Bladder Tank – 79 Gallon (Vertical Mounting)

- Model Reference: Vertical Foam Bladder Tank with 3″ Ratio Flow Controller

- Brand: BRISTOL

- Capacity: 79 gallons (≈ 300 liters)

- Design Code: ASME Section VIII, Div. I – Latest Edition

- Working Pressure: 12.06 bar (175 psi)

- Hydrostatic Test Pressure: 18.09 bar (263 psi)

- Mounting Orientation: Vertical

- Internal Finish: Coal Tar Epoxy

- External Finish: Epoxy – Flame Red (RAL 3000)

- Bladder Material: Nylon Reinforced Nitrile Rubber (BUNA-N)

- Foam Compatibility: UL listed for AFFF 3% and AR-AFFF 3×3%

- Ratio Flow Controller Size: 3” (DN80)

- Flow Range: 200–3200 LPM

- Proportioning Ratio: 3%

- Application Areas: Oil refineries, chemical plants, aircraft hangars, offshore platforms

- Construction Material: Carbon steel vessel, stainless steel valves and piping

- Standard Accessories: Level gauge, water/foam piping, relief valves, bladder drain, vessel drain

For more information, visit our website: https://silverstringchemicals.com/

Connect with us on social media:

- LinkedIn: Silver String Chemicals

- TikTok: @silverstringchemicals

- YouTube: Silver String Chemicals

- Instagram: @silverstringchemicals_ssc

- Facebook: Silver String Chemicals

Contact us via email at: silverstringchemicals@gmail.com

| ALL PRICES MENTIONED ON SSC SHOP: Ex-Works Factory, Lahore, Pakistan. | |||||

| FREIGHT CHARGES & TAXES ARE EXCLUDED | |||||

| 90% Advance & 10% Before Delivery Is Must. | |||||

| Delivery: 4 days to 30 days, Depending On Local Supplies or Imports. | |||||

| We Provide Services For Testing, Commissioning & Fittings As Well. | |||||

| Stock Availability Will Be Checked & Communicated To You After We Receive Your Quantity/Standard. | |||||

| Items Were Last Updated In June 2023. |

Bristol UL Listed Foam Bladder Tank – 79 Gallon (Vertical Mounting)

Reliable Foam Storage & Proportioning for Industrial Fire Protection

🔥 Overview: Compact Vertical Foam TANK for Critical Environments

The Bristol UL Listed 79-Gallon Foam Bladder Tank is a compact and efficient firefighting solution. Built for high-risk areas like oil refineries, offshore platforms, aircraft hangars, and chemical plants, this vertical tank stores and delivers foam with unmatched reliability.

With a total capacity of 79 gallons (300 liters), the tank enables rapid and accurate foam deployment during emergencies—providing peace of mind where response time is vital.

🏗️ TANK Construction: Built to ASME & UL Standards

This vertical tank is manufactured according to ASME Section VIII, Division I – Latest Edition, ensuring compliance with the most trusted engineering codes.

-

Working Pressure: 12.06 bar (175 psi)

-

Test Pressure: 18.09 bar (263 psi)

-

UL Listing: Approved for AFFF 3% and AR-AFFF 3×3% foam

As a result, the tank performs under high pressure and harsh conditions—making it suitable for global industrial and energy sector deployments.

🧱 TANK Design: Space-Saving Vertical Configuration

The vertical mounting helps conserve floor space, especially in offshore, confined, or modular installations. Internally, the tank is coated with coal tar epoxy to protect against corrosion caused by foam concentrates.

Externally, it features a RAL 3000 epoxy red finish for weatherproofing and high visibility in industrial fire zones.

🫧 Internal Bladder – Core of the TANK System

At the heart of this tank is a nylon-reinforced nitrile rubber bladder (BUNA-N). This advanced liner separates foam concentrate from water, preventing contamination and ensuring precise proportioning.

Benefits of the bladder system:

-

Superior chemical resistance

-

Prevents foam degradation

-

Maintains performance consistency

-

Extends tank service life

Because of this design, the tank operates cleanly, with minimal intervention or downtime.

🌐 Foam Compatibility: TANK Supports AFFF and AR-AFFF

This tank is fully UL listed for AFFF 3% and AR-AFFF 3×3% foam concentrates, allowing it to combat Class B fires, including:

-

Hydrocarbons (like gasoline, diesel, and oil)

-

Polar solvents (like alcohols and ketones)

This flexibility makes it ideal for dual-risk environments with mixed fuel hazards.

🔄 Proportioning Accuracy with 3” Flow Controller

The tank includes a 3” (DN80) UL-listed ratio controller that mixes water and foam concentrate at a precise 3% ratio. It supports a broad flow range of 200 to 3200 LPM, making it ideal for:

-

Foam monitors

-

Sprinkler systems

-

Hose reels

Thus, the tank integrates easily with a wide array of foam suppression setups.

⚙️ TANK Materials: Rugged & Corrosion-Resistant Construction

Made from carbon steel, the tank’s outer shell provides mechanical strength and stability. Internally, all wetted parts—including valves and piping—are fabricated from stainless steel to ensure resistance against rust, chemical damage, and abrasive wear.

Together, these materials lower maintenance requirements and extend the system’s service life.

🔧 Fully Equipped Vertical TANK System

Every tank comes ready for action with essential operational accessories:

-

✅ Liquid level gauge for easy monitoring

-

✅ Relief valves for overpressure protection

-

✅ Bladder and vessel drains for maintenance

-

✅ Foam and water inlet/outlet piping for seamless connection

These features simplify inspection, servicing, and daily operation, reducing response delays during emergencies.

✅ Conclusion: TANK Performance You Can Trust

The Bristol 79 Gallon Vertical Foam Bladder Tank is an ideal fire suppression system for demanding industrial settings. With UL approvals, accurate proportioning, and durable materials, it offers a low-maintenance, high-efficiency foam delivery platform.

Whether you’re protecting a fuel depot, a chemical facility, or an offshore rig, this tank provides the power and precision your emergency response team needs—when every second matters.