Fire Fighting Truck

Vehicle Chassis and Engine Details

The fire fighting vehicle will be based on the ISUZU NPR 71 truck chassis. This chassis supports a gross vehicle weight of 8,800 kg or more. The engine must deliver at least 122/3000 HP/RPM, with a displacement of 4,400 cc or more. It will feature a four-cylinder, four-cycle, direct injection, in-line, water-cooled, overhead camshaft engine, which is turbocharged for enhanced performance.

Construction of Cabin and Body

Body Fabrication

The body will be constructed from mild steel channels of 4 mm thickness and angles of at least 2 mm thickness, joined by welding. It will be covered with 16 SWG aluminum sheets on the exterior and feature chequered aluminum on the interior. All materials used will be new and free of defects. The body will be treated and painted for high rust resistance.

The roof and walking platforms will be covered with aluminum checker plates of a minimum of 16 gauges. A ladder and non-slippery steps will provide roof access, with protective plates and handrails for safety. The vehicle will include a towing hook at both the front and rear, with easy access to the pump for maintenance. Spare wheels will be fitted to prevent water leakage from the pump compartment.

Suitable storage tunnels will be provided for suction hoses. All fabrication will ensure user-friendliness, with no sharp edges. Side lockers will be included for standard accessories, and tool boxes will be made of aluminum alloy checkered sheets. These tool boxes will have stainless steel locks and anodized aluminum shutters. Special compartments will be available for hanging fire suits. The roof will have an SS round pipe border for safety and equipment securing. The base will be coated with anti-rust epoxy paint, and the storage bay/tool kit boxes will be finished with 2K paint for enhanced aesthetics. Additional leaf springs will be installed to increase the vehicle’s loading capacity.

Crew Cabin Design

A separate crew cabin will be constructed behind the driver’s cabin, featuring steel welded construction with a torsion bar tilt mechanism and additional safety door impact beams. It will have sliding glass windows and metallic paint. This cabin will accommodate 3-4 firefighters and be made with high-quality galvanized sheets. Seats will be well-cushioned, with seat belts and Rexene upholstery. The cabin will also feature LED interior lights and two revolving fans, along with an intercom for communication.

Electrical System and Lighting

Electrical Installations

The vehicle’s electrical system will operate on a 12/24 V power supply. This system will power all emergency, internal, and external lighting, as well as the PA system. Internal strip lights will illuminate the rear compartments for easy equipment access. Each storage bay will have separate strip lights, all using LED technology.

Electrical wiring will use a harness system to minimize faults. A separate fuse box will isolate electrical issues. Wires will be fire-retardant and sized according to load requirements. The driver’s cabin will feature a 12/24 V control panel. Flood lights of 20 to 30 watts will be installed around the vehicle for nighttime operations.

Warning Bar Light and PA System

A main LED warning light in red and blue will be mounted on a special spoiler on the roof of the front cabin. The vehicle will also feature red and blue warning lights on all sides, with two sets on each side. Additionally, a 100/150W PA system with a speaker and microphone will be included.

Vehicle Branding and Equipment

Branding of the Vehicle

The vehicle will have a unique and visually striking branding design to enhance its appearance and reflect the organization’s identity. Clear labeling and marking will be provided for all storage areas to ensure efficient use of equipment and tools.

Equipment Installations

The equipment cabin and boxes will be designed to secure equipment and prevent damage during transit. Shelves within partitions will maximize space usage, and fittings with straps will secure small equipment.

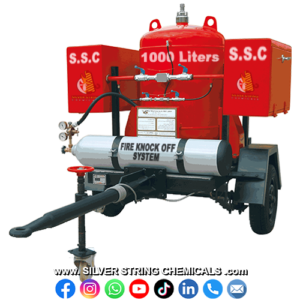

Water and Foam Tanks

Water Tank Specifications

The water tank will have a minimum capacity of 4,500-5,000 liters, made of mild steel with a thickness of 4 mm. It will be mounted on heavy-duty neoprene bearing pads and include 2-3 removable baffle plates. A glass tube level indicator will be included, along with a 600 mm diameter manhole and a 2 ½’’ instantaneous coupling for hydrant filling. Drainage points will feature 2 ½’’ ball valves.

Foam Tank Specifications

The foam tank will have a minimum capacity of 1,000-1,500 liters, made of mild steel with a thickness of 4 mm. It will feature a glass tube level indicator and a 400 mm diameter manhole. A 1 ½’’ coupling will be used for discharge.

Fire Pump and Controls

Fire Pump Specifications

The fire pump will be a centrifugal type with a built-in gearbox, delivering a minimum of 2,000-2,250 Lpm at 10 Bar. The casing will be made of SG iron, with a bronze impeller and mild steel impeller shaft. It will include a mechanical seal and a 4” NPT suction. The pump will have 4 x 65 mm delivery outlets and one outlet for a ¾” hose reel. The main body will be made of SS, gunmetal, or aluminum alloy.

Pump Control Features

The pump will include controls for engine throttle, priming, pressure gauges, and various valves. A control panel with lights and switches, an RPM meter, and a manual bypass control for the pump to tank will be included.

PTO and Water Monitor

PTO Specifications

A split shaft PTO will be provided according to vehicle specifications.

Water Monitor Features

The water monitor, mounted on the vehicle’s top, will be made of mild steel and will provide a minimum discharge of 2,000 Lpm with a 30-meter throw. It will rotate 360 degrees and have an elevation range of +70 to -15 degrees. The adjustable nozzle will deliver 1,100 Lpm with a range of 30 meters at 10 Bars.

Additional Equipment

Hose Reel and CO2 System

A 1” x 30-meter high-pressure rubber hose reel with a 100 Lpm nozzle and a range of 25 meters will be located at the rear of the vehicle. The CO2 system will include one 50 kg cylinder with a 10-foot delivery hose and a discharge horn/nozzle on the hose reel.

BOQ Items

- Gallons Branch Nozzle (China): Selectable gallonage branch nozzle ranging from 115-475 LPM.

- Jet Nozzle (China): Inlet: 63mm (2.5”) male instantaneous BS-336, with a solid jet stream.

- Multipurpose Nozzle (China): Flow rate of 200-250 LPM, with an operating pressure of 3.5 to 7 bar.

- Suction Wrenches: Local made and stored in compartments.

- Extension Ladder: 30 feet, light aluminum alloy, two sections.

- Search Light: High-intensity search lights, rust-proof, two in front and two at the rear.

- Rechargeable Hand-Held LED Search Lights: Minimum 500 lumens with charging option.

- Suction Hose (4”): 4” x 3 meters with gunmetal coupling.

- Copper Strainer (Local): Local made copper strainer.

- Basket Strainer: One basket strainer provided.

- Fire Hook: Local made fiberglass fire hooks.

- Fire Crow Bar (Local): Local made fire crow bar.

- Fireman Axe: With an insulated handle.

- Fireman Gum Boots: Special fireman gum boots provided.

- DCP Fire Cylinder: 6 kg capacity, from China.

- First Aid Box: Basic first aid box with standard items.

- Fire Suit Nomex (China): Full fire suit provided.

- Delivery Hoses: 2.5” x 100 feet with coupling.

- SCBA (China): Imported SCBA with cylinder, face mask, and accessories

For more information, visit our website: https://silverstringchemicals.com/

Connect with us on social media:

- LinkedIn: Silver String Chemicals

- TikTok: @silverstringchemicals

- YouTube: Silver String Chemicals

- Instagram: @silverstringchemicals_ssc

- Facebook: Silver String Chemicals

Contact us via email at: silverstringchemicals@gmail.com