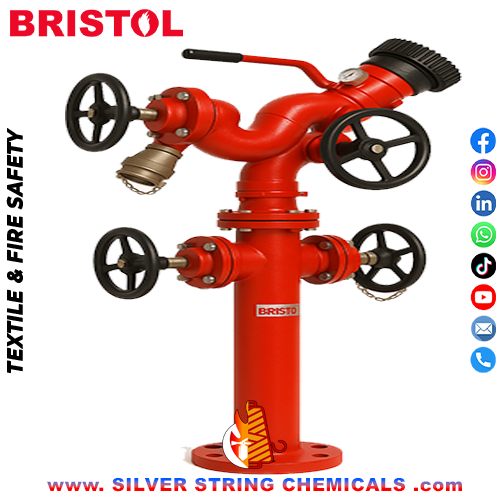

Bristol 4″ Flanged Wet Barrel Fire Hydrant (BFE-WT04D) + Fire Water Monitor 500 GPM – UL Listed

- Model: BFE-WT04D

- Type: 2×2.5″ F. Inst.

- Inlet: 4″ Flanged

- Valve: Globe Type

- Coating: Powder Coated

- Body: Ductile + Cast Iron

- Operating Turns: 10.5

- Drain Valve: Auto drain system

- Freeze Proof: Yes

- Pressure: 16 bar

- Test Pressure: 24 bar

- Valve Standard: BS EN14384

- Color: Red

- Kitemark Certified: Yes

- Use: Municipal or building hydrant

- Outlet: BS336

- Fire Water Monitor 500 GPM – UL Listed

- Material: Stainless Steel | Brand: BRISTOL

- Flow Rate: 500 GPM

- Material: Stainless Steel

- Pressure: 100 PSI

- Nozzle Type: Manual/Auto

- Mount: Flanged or fixed base

- Rotation: 360° Horizontal

- Elevation: 30° to 80°

- Control: Manual

- Finish: Red enamel

- Weight: ~20–30 kg

- Application: Fixed fire monitor

- Stream Type: Jet/Fog

- Compliance: UL Listed

- Thread: ANSI standard

- Use: Tank farms, fire lines.

- Adapter (2 ½ inch F.NST/NH x 2 ½ inch BS336 F. Inst., Brass, with Blank Cap and Chain)

For more information, visit our website: https://silverstringchemicals.com/

Connect with us on social media:

- LinkedIn: Silver String Chemicals

- TikTok: @silverstringchemicals

- YouTube: Silver String Chemicals

- Instagram: @silverstringchemicals_ssc

- Facebook: Silver String Chemicals

Contact us via email at: silverstringchemicals@gmail.com

| ALL PRICES MENTIONED ON SSC SHOP: Ex-Works Factory, Lahore, Pakistan. | |||||

| FREIGHT CHARGES & TAXES ARE EXCLUDED | |||||

| 90% Advance & 10% Before Delivery Is Must. | |||||

| Delivery: 4 days to 30 days, Depending On Local Supplies or Imports. | |||||

| We Provide Services For Testing, Commissioning & Fittings As Well. | |||||

| Stock Availability Will Be Checked & Communicated To You After We Receive Your Quantity/Standard. | |||||

| Items Were Last Updated In June 2023. |

4″ Flanged Wet Barrel Hydrant (BFE-WT04D) with 500 GPM UL-Listed BRISTOL Fire Monitor

Reliable, High-Pressure Fire Protection for Industrial and Municipal Networks

Overview

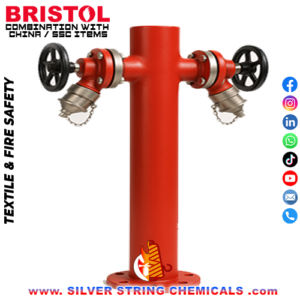

The BFE-WT04D 4” Flanged Wet Barrel Fire Hydrant, paired with a UL-Listed 500 GPM BRISTOL Fire Water Monitor, is a rugged and high-performing firefighting solution built for demanding environments. Designed for use in municipal hydrant networks, industrial plants, fire lines, and tank farms, this combination offers powerful water delivery, corrosion resistance, and international standard compliance. Whether deployed in a commercial complex or a hazardous zone, it delivers reliable performance where fire safety is mission-critical.

Wet Barrel Hydrant – Model BFE-WT04D

The wet barrel hydrant features a 4-inch flanged inlet and an internal globe-type valve, engineered for controlled water flow and dependable shutoff. The valve is designed to open fully in 10.5 turns, providing a smooth and responsive operation.

Manufactured from a combination of ductile iron and cast iron, the hydrant body is powder-coated in red for high visibility and protection against rust. An auto-drain valve system is built-in, allowing water to exit the hydrant after use. This feature makes the system freeze-proof, ensuring it performs in both hot and cold climates.

The hydrant supports a working pressure of 16 bar and withstands a test pressure of 24 bar, which qualifies it for high-pressure fire suppression systems. Additionally, it complies with BS EN14384 and is Kitemark certified, ensuring its quality and durability meet stringent international firefighting standards.

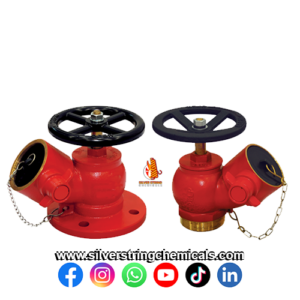

Dual 2.5” Outlets for Fire Hose Connection

The hydrant is fitted with two 2.5” BS336 female instantaneous outlets, which are compatible with standard firefighting hose fittings. This enables first responders to rapidly deploy hoses, reducing fire response time during emergencies.

Key Benefits:

-

Compatible with global firefighting hose standards

-

Durable build for long-term service

-

Easy access to water during fire outbreaks

-

Automatic draining prevents freeze-related damage

UL-Listed BRISTOL 500 GPM Fire Water Monitor

Integrated with the hydrant is a manual fire water monitor from BRISTOL, designed for 500 GPM flow at 100 PSI pressure. Built from stainless steel and finished in high-visibility red enamel, this monitor is corrosion-resistant and ideal for fixed, long-term installations in open or hazardous environments.

It allows 360° horizontal rotation and 30° to 80° vertical elevation, providing complete control over the direction of the water or foam stream. Operators can adjust the nozzle between jet and fog modes, depending on the fire situation. Additionally, both manual and automatic nozzle versions are available, offering flexibility based on response requirements.

A streamlined internal structure reduces friction and minimizes pressure drop, ensuring water is delivered with force and efficiency. The unit can be mounted via flange or fixed base, making it adaptable for hydrant tops, platforms, or vehicle mounts.

Monitor Features:

-

UL Listed for global compliance

-

500 GPM flow rate for high-volume discharge

-

Stainless steel body for weather and chemical resistance

-

Precision control for direction and spray pattern

-

Compatible with AFFF and other standard foam concentrates

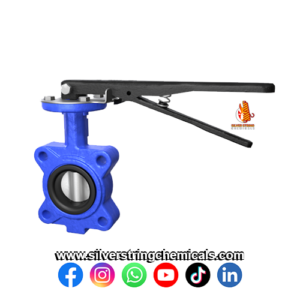

Adapter and Thread Compatibility

To support varied connection requirements, the system includes a brass adapter (2½” F.NST/NH × 2½” BS336 F. Inst.). This makes it compatible with ANSI-standard threads, ensuring cross-system functionality. A blank cap and safety chain are provided to protect the outlet from dust and damage when not in use.

Applications

This combined hydrant and fire monitor setup is ideal for:

-

🏭 Oil & Gas Facilities

-

🏢 Commercial Complexes and Warehouses

-

🚒 Municipal Hydrant Networks

-

🛢️ Fuel Storage Zones and Chemical Plants

-

🧯 Industrial Fire Safety Installations

Conclusion

The BFE-WT04D Wet Barrel Fire Hydrant, together with the UL-listed BRISTOL Fire Water Monitor, forms a powerful firefighting system ready to respond to serious fire threats. Offering high pressure, wide coverage, and dual operational capability, this solution is perfectly suited for critical fire zones.

Built with international certifications, freeze protection, and manual control precision, this system supports both hose deployment and long-range monitor suppression—making it a preferred choice for engineers, facility safety teams, and firefighting professionals across industries.